Published on the 30/03/2015 | Written by Alan Earls, Vinod Baya

The technology for 3D printing has existed in some form since the 1980s. Now it is poised to move beyond prototyping into end-product and high-volume commercial manufacturing. Vinod Baya, director of PwC’s Centre for Technology and Innovation, and Alan Earls look at the coming changes and challenges for 3D printing…

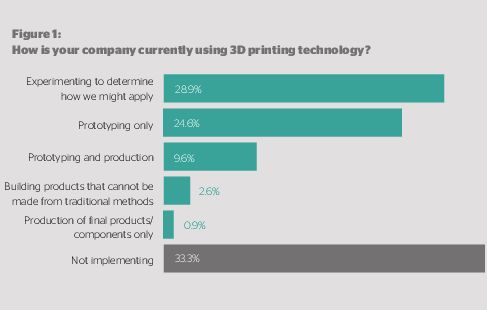

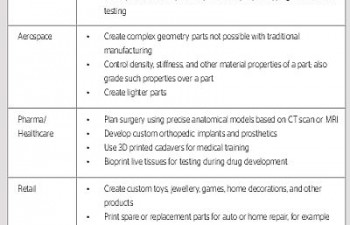

In a recent PwC survey of more than 100 industrial manufacturers, two-thirds were already using 3D printing. (See Figure 1.) Most were just experimenting or using it only for rapid prototyping, which has been 3D printing’s center of gravity for most of its history. Canalys, a market research firm, anticipates changes ahead and predicts the global market for 3D printers and services will grow from US$2.5 billion in 2013 to US$16.2 billion in 2018, a CAGR of 45.7 percent. Several technology trends are pointing to these changes, but despite this the 3D printing industry faces challenges. Rapid prototyping will remain important but is not the game-changer that will expand the technology into high-volume use cases. The industry should pivot to printing more fully functional and finished products or components in volumes that greatly outnumber the volumes of prototypes produced. For example, some makers of hearing aids and dental braces have adopted the technology for finished products. In addition, 3D printing should supplement or supplant products and components manufactured traditionally and create items that can be manufactured in no other way. To evolve their design and manufacturing strategies, many industry sectors are using 3D printing solutions already in the market. (See Table 1.) Technology for 3D printing will advance through loosely co-ordinated development in three areas: printers and printing methods, software to design and print, and materials used in printing. The emerging shape of the 3D printer industry Performance: Improve speed, resolution, autonomous operation, ease of use, reliability, and repeatability. Today’s 3D printers are concentrated at two ends of a spectrum: high cost–high capability and low cost–low capability. During the past year, a new class of printers in the middle has emerged. These printers from new entrants and established vendors have many of the higher-end capabilities at lower prices. For example, printers from FSL3D and Formlabs deliver higher resolution and smaller size using stereolithography technology and are priced at a few thousand dollars. Printers from MarkForged offer the ability to print using carbon fiber composites in a desktop form factor for less than US$5000. CubeJet from 3D Systems is priced under US$5000, can print in multiple colors, and brings professional features to a lower price point. Gartner predicts that 3D printers with the value (capabilities and performance) that is demanded by businesses and other organisations will be available for less than US$1000 by 2016. It is fair to expect that printer improvements will accelerate in the next few years, although the degree and nature of these changes will vary considerably across printing technologies and vendors. Trends in 3D printer performance Speed: Even for simple products, 3D printing still takes too long — usually hours and sometimes days. Incremental improvements as well as new methods that have the potential for an order of magnitude change will help printers meet the challenge for greater speed. “There are lots of ways to improve speed by using higher quality components and by optimising the designs and movement of the lasers,” says Andrew Boggeri, lead engineer at FSL3D, a provider of desktop stereolithography printers. Most of today’s printers use a single printhead to deposit material. Adding more printheads that print at the same time can increase speed by depositing material faster, while incorporating multiple materials or multiple colors of the same material. Multiple heads can also make many copies of the same design in the time it takes to print one. With such innovation, print speed can increase more or less linearly as the number of heads increases. Speed is especially a challenge when printing larger objects. A partnership between Oak Ridge National Laboratory and Cincinnati Incorporated, a machine tool manufacturer, is addressing this challenge. The organisations are developing a large-scale additive manufacturing system. Their design will combine larger nozzles for faster polymer deposition, high-speed laser cutters that handle work areas in feet rather than inches, and high-speed motors to accelerate the pace at which printer heads are moved into position. The result will be a system capable of printing polymer components as much as 10 times larger, and at speeds 200 to 500 times faster than existing additive machines. To control the movement of the printer head, 3D printers use different approaches or architectures. Cartesian printers, which move a printhead in two dimensions on a plane, are the popular configuration today. Deltabot printers, also called Delta robot printers, use parallelograms in the arms like a robot “The Delta printers are going to basically take over all the Cartesian printers, because they have some significant benefits, one of which is speed,” predicts Joshua Pearce, associate professor at Michigan Technological University (MTU) and an active developer of open source 3D printers. Delta configuration allows for higher speed, because the printheads are lighter and they use shorter paths from one point to another. Ease of use: Existing 3D printers perform many tasks autonomously, however, some printers at the hobbyist end require that printheads be cleaned periodically, that beds be properly levelled, and that a human tinker and supervise to minimise errors. Automating the features that cause many of the common errors and reliability concerns (such as support structure generation, part orientation) will be a key area of innovation over the next few years and will likely advance the ease of use in hobbyist printers. For instance, a print run can be wasted if the build platform is not level. Many printers, such as those from Robox, XYZprinting, and MakerBot, include autolevelling. Expected in the future is a feedback system that provides real-time monitoring of the printing process, that detects defects or deviation from the specified design, and that allows appropriate intervention. Together, such features will likely improve the reliability and repeatability of the printing process. How 3D printers deal with materials The pursuit of multi-material capability will favour certain printing methods over others. Fused filament fabrication (FFF) printing has high potential to accommodate multiple materials without greatly extending the existing technology, because printing heads can be added to handle other polymers. “For multi-material printing, inkjetlike technology such as Voxeljet is the present and the future,” Boggeri predicts. Methods such as selective laser sintering and others use inkjet technology. This technology can handle multiple materials within a range that can be delivered as a powdered ‘base’ because it already uses multiple printheads. As a result, parts or assemblies made from different materials can be printed in a single print run. Today this technology is accessible at the high end from Voxeljet, Stratasys, 3D Systems, and others. Inkjet printing for 2D printers has been around since the 1970s, but was adopted for 3D printing only about seven years ago by Objet (now part of Stratasys) in a process the company calls PolyJet. By jetting two or more base materials in varying combinations, this technology allows the creation of new material properties that span from rigid plastic to rubber-like and from opaque to transparent. More recently, the technology also allows the printing of multiple colours. For example, the Stratasys Objet500 Connex3 printer supports multi-material and multi-coloured 3D printing. A printed part can have as many as 14 distinct material properties and 10 colour palettes. Today, multi-material printers work for a single family of materials – polymers, for instance – and are largely used for prototyping so designers can check form, function, fit, and feel. Advances are still needed to combine different families of materials, such as metals and plastics, in a single print cycle. Developments on this front are in very early stages in research labs, and it will likely be more than five years before products are offered. “As 3D printers become faster, easier to use, handle multiple materials, and print active components or systems, they will find use beyond rapid prototyping.” Printing complete systems The key materials science challenge is to develop inks (the term inks refers to all material in 3D printing that is either extruded or jetted out of a nozzle) that can be the basis for printing different types of products, be they sensors, electronics, or batteries. For example, Xerox PARC is developing inks so circuits, antennas, and RFID tags can be printed and applied directly to a product. Similarly, Professor Jennifer A. Lewis at the Harvard School of Engineering and Applied Sciences has developed the basic building block of tiny lithiumion batteries as inks that can be printed. The future of additive manufacturing is not limited to inanimate objects. Lewis’s team has developed bioinks to make living tissues. The team uses multiple printheads and the customised inks to create complex living tissues, complete with tiny blood vessels. Some pharmaceutical companies are already using 3D printed tissue for testing drugs. Bio-printing typically uses two inks. One is the biological material and the other is hydrogel that provides the environment where the tissue and cells grow. The breakthrough to add blood vessels was the development of a third ink that has an unusual property: it melts as it cools, not as it warms. This property allowed scientists to print an interconnected network of filaments and then melt them by chilling the material. The liquid is siphoned out to create a network of hollow tubes, or vessels, inside the tissue. Such creations are possible only with 3D printing, generating new possibilities beyond traditional manufacturing. The printing of complete systems is not limited to a nano or microscopic scale. Working with Aurora Flight Sciences and Stratasys, Optomec has printed complete aeroplane wings, including electronics and sensors, for small drones. Some approaches may combine 3D printing with other manufacturing methods. For example, iRobot has filed a patent for a fully automated robotic 3D printer, including multiple manipulators and milling, drilling, and other processes to make final products. “Technology for 3D printing will advance through loosely co-ordinated development in three areas: printers and printing methods, software to design and print, and materials used in printing.” The pace of innovation Another key factor that will likely change soon is the control that patent holders have had over specific techniques. When key patents for FFF expired five years ago, the open source community rapidly incorporated the techniques in low-cost printers, triggering improvements in speed, quality, resolution, and ease of use. Likewise, many laser-sintering patents were set to expire by the end of 2014. If the pace of innovation is as rapid as it was with FFF printers, then less expensive desktop metal printers may appear within a few years. Today’s market for 3D printers and services is still largely bifurcated – at the low end are limited function offerings and at the high end are extremely expensive printers. The key for market growth is the continuing development of printers in the middle price range to achieve advances in performance, in multi-material capability, and in printing complete systems. *This article was originally published in Q4 2014 by PwC’s Centre for Technology and Innovation (CTI), as part of its Technology Forecast series. … Where access and governance meet… Getting practical on building AI maturity… More than just cybersecurity… Asset-centric industries are ripe for an AI revolution, but without the hype… Are buyers looking for AI features? Or is the reverse more true?

3D printers must be improved in three areas to seize the opportunities that exist beyond today’s predominant use case of rapid prototyping:

Multi-material capability and diversity: Incorporate multiple types of materials, including the ability to mix materials while printing a single object.

Finished products: Provide the ability to print fully functional and active systems that incorporate many modules, such as embedded sensors, batteries, electronics, microelectromechanical systems (MEMS), and others.

While many characteristics define a printer’s performance, the key challenges are speed and ease of use.

Most printers work with only one type of material — plastic, metal, ceramic, wood, or a biological material. To create more useful products and expand the market, 3D printers will need to process multiple material types within a single build cycle. Various factors, mostly related to materials themselves, make this requirement challenging. For example, most processes are built around an ideal material that responds to a narrow range of temperature inputs or light frequency, preventing the use of other potential materials – at least at the current level of sophistication.

Most printers work with only one type of material — plastic, metal, ceramic, wood, or a biological material. To create more useful products and expand the market, 3D printers will need to process multiple material types within a single build cycle. Various factors, mostly related to materials themselves, make this requirement challenging. For example, most processes are built around an ideal material that responds to a narrow range of temperature inputs or light frequency, preventing the use of other potential materials – at least at the current level of sophistication.

Farther out is the ability to print complete systems or subsystems. Emerging multi-material capabilities will help, since most finished products are made from more than one material. However, challenges extend to the ability to embed components such as sensors, electronics, and batteries, so everything can be printed in one build. R&D efforts are under way in a number of areas, including materials, printing methods, and combining additive and traditional methods of manufacturing. 3D printed furniture by French company Drawn

3D printed furniture by French company Drawn

The 3D printer market is transforming rapidly. Robust innovation at established vendors and among entrepreneurs and hobbyists is providing a test ground for filling the market with more midrange systems that bring enterprise-class capabilities at much lower prices.FURTHER READING

Cyber resilience begins with modern identity security

Asset management leaders share AI insights

Identity security as a business transformer

Don’t run before you can walk with AI

The evolving role of AI in business technology