Published on the 20/02/2017 | Written by Henry Hazlitt

Among the most viable of all economic delusions is the belief that machines on net balance create unemployment…

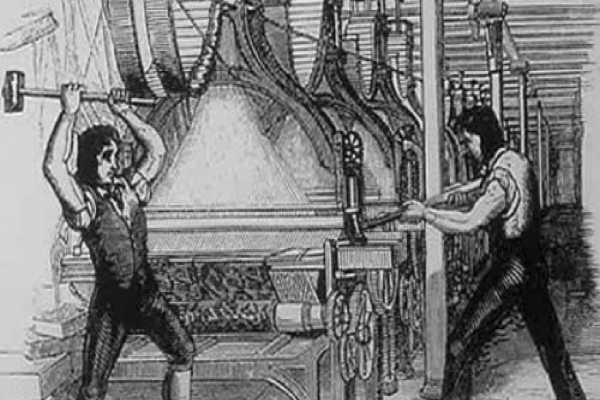

Destroyed a thousand times, it has risen a thousand times out of its own ashes as hardy and vigorous as ever. Whenever there is long-continued mass unemployment, machines get the blame anew. This fallacy is still the basis of many labor union practices. The public tolerates these practices because it either believes at bottom that the unions are right, or is too confused to see just why they are wrong. The belief that machines cause unemployment, when held with any logical consistency, leads to preposterous conclusions. Not only must we be causing unemployment with every technological improvement we make today, but primitive man must have started causing it with the first efforts he made to save himself from needless toil and sweat. To go no further back, let us turn to Adam Smith’s The Wealth of Nations, published in 1776. The first chapter of this remarkable book is called “Of the Division of Labor,” and on the second page of this first chapter the author tells us that a workman unacquainted with the use of machinery employed in pin-making “could scarce make one pin a day, and certainly could not make twenty,” but that with the use of this machinery he can make 4,800 pins a day. So, already, alas, in Adam Smith’s time, machinery had thrown from 240 to 4,800 pin-makers out of work for every one it kept. In the pin-making industry there was already, if machines merely throw men out of jobs, 99.98 per cent unemployment. Could things be blacker? Things could be blacker, for the Industrial Revolution was just in its infancy. Let us look at some of the incidents and aspects of that revolution. Let us see, for example, what happened in the stocking industry. New stocking frames as they were introduced were destroyed by the handicraft workmen (over 1,000 in a single riot), houses were burned, the inventors were threatened and obliged to fly for their lives, and order was not finally restored until the military had been called out and the leading rioters had been either transported or hanged. A Short-Sighted Approach Arkwright invented his cotton-spinning machinery in 1760. At that time it was estimated that there were in England 5,200 spinners using spinning wheels, and 2,700 weavers—in all 7,900 persons engaged in the production of cotton textiles. The introduction of Arkwright’s invention was opposed on the ground that it threatened the livelihood of the workers, and the opposition had to be put down by force. Yet in 1787—twenty-seven years after the invention appeared—a parliamentary inquiry showed that the number of persons actually engaged in the spinning and weaving of cotton had risen from 7,900 to 320,000, an increase of 4,400 per cent. If the reader will consult such a book as Recent Economic Changes, by David A. Wells, published in 1889, he will find passages that, except for the dates and absolute amounts involved, might have been written by our technophobes (if I may coin a needed word) of today. Let me quote a few: During the ten years from 1870 to 1880, inclusive, the British mercantile marine increased its movement, in the matter of foreign entries and clearances alone, to the extent of 22,000,000 tons… yet the number of men who were employed in effecting this great movement had decreased in 1880, as compared with 1870, to the extent of about three thousand (2,990 exactly). What did it? The introduction of steam-hoisting machines and grain elevators upon the wharves and docks, the employment of steam power, etc…. In 1873 Bessemer steel in England, where its price had not been enhanced by protective duties, commanded $80 per ton; in 1886 it was profitably manufactured and sold in the same country for less than $20 per ton. Within the same time the annual production capacity of a Bessemer converter has been increased fourfold, with no increase but rather a diminution of the involved labor. The power capacity already being exerted by the steam engines of the world in existence and working in the year 1887 has been estimated by the Bureau of Statistics at Berlin as equivalent to that of 200,000,000 horses, representing approximately 1,000,000,000 men; or at least three times the working population of the earth…. One would think that this last figure would have caused Mr. Wells to pause, and wonder why there was any employment left in the world of 1889 at all; but he merely concluded, with restrained pessimism, that “under such circumstances industrial overproduction … may become chronic.” Technocrats Revive Old Errors The Technocrats were finally laughed out of existence; but their doctrine, which preceded them, lingers on. It is reflected in hundreds of make-work rules and featherbed practices by labor unions; and these rules and practices are tolerated and even approved because of the confusion on this point in the public mind. Testifying on behalf of the United States Department of Justice before the Temporary National Economic Committee (better known as the TNEC) in March, 1941, Corwin Edwards cited innumerable examples of such practices. The electrical union in New York City was charged with refusal to install electrical equipment made outside of New York State unless the equipment was disassembled and reassembled at the job site. In Houston, Texas, master plumbers and the plumbing union agreed that piping prefabricated for installation would be installed by the union only if the thread were cut off one end of the pipe and new thread cut at the job site. Various locals of the painters’ union imposed restrictions on the use of spray guns, restrictions in many cases designed merely to make work by requiring the slower process of applying paint with a brush. A local of the teamsters’ union required that every truck entering the New York metropolitan area have a local driver in addition to the driver already employed. In various cities the electrical union required that if any temporary light or power was to be used on a construction job there must be a full-time maintenance electrician, who should not be permitted to do any electrical construction work. This rule, according to Mr. Edwards, “often involves the hiring of a man who spends his day reading or playing solitaire and does nothing except throw a switch at the beginning and end of the day.” One could go on to cite such make-work practices in many other fields. In the railroad industry, the unions insist that firemen be employed on types of locomotives that do not need them. In the theaters unions insist on the use of scene shifters even in plays in which no scenery is used. The musicians’ union required so-called “stand-in” musicians or even whole orchestras to be employed in many cases where only phonograph records were needed. By 1961 there was no sign that the fallacy had died. Not only union leaders but government officials talked solemnly of “automation” as a major cause of unemployment. “Automation” was discussed as if it were something entirely new in the world. It was in fact merely a new name for continued technological advance and further progress in labor-saving equipment. One might pile up mountains of figures to show how wrong were the technophobes of the past. But it would do no good unless we understood clearly why they were wrong. For statistics and history are useless in economics unless accompanied by a basic deductive understanding of the facts—which means in this case an understanding of why the past consequences of the introduction of machinery and other labor-saving devices had to occur. Otherwise the technophobes will assert (as they do in fact assert when you point out to them that the prophecies of their predecessors turned out to be absurd): “That may have been all very well in the past; but today conditions are fundamentally different; and now we simply cannot afford to develop any more laborsaving machines…. We have reached a point today where laborsaving devices are good only when they do not throw the worker out of his job.” If it were indeed true that the introduction of labor-saving machinery is a cause of constantly mounting unemployment and misery, the logical conclusions to be drawn would be revolutionary, not only in the technical field but for our whole concept of civilization. Not only should we have to regard all further technical progress as a calamity; we should have to regard all past technical progress with equal horror. Every day each of us in his own capacity is engaged in trying to reduce the effort it requires to accomplish a given result. Each of us is trying to save his own labor, to economize the means required to achieve his ends. Every employer, small as well as large, seeks constantly to gain his results more economically and efficiently—that is, by saving labor. Every intelligent workman tries to cut down the effort necessary to accomplish his assigned job. The most ambitious of us try tirelessly to increase the results we can achieve in a given number of hours. The technophobes, if they were logical and consistent, would have to dismiss all this progress and ingenuity as not only useless but vicious. Why should freight be carried from New York to Chicago by railroads when we could employ enormously more men, for example, to carry it all on their backs? A Case in Point Suppose a clothing manufacturer learns of a machine that will make men’s and women’s overcoats for half as much labor as previously. He installs the machines and drops half his labor force. This looks at first glance like a clear loss of employment. But the machine itself required labor to make it; so here, as one offset, are jobs that would not otherwise have existed. The manufacturer, however, would have adopted the machine only if it had either made better suits for half as much labor, or had made the same kind of suits at a smaller cost. If we assume the latter, we cannot assume that the amount of labor to make the machines was as great in terms of payrolls as the amount of labor that the clothing manufacturer hopes to save in the long run by adopting the machine; otherwise there would have been no economy, and he would not have adopted it. So there is still a net loss of employment to be accounted for. But we should at least keep in mind the real possibility that even the first effect of the introduction of labor-saving machinery may be to increase employment on net balance; because it is usually only in the long run that the clothing manufacturer expects to save money by adopting the machine: it may take several years for the machine to “pay for itself.” After the machine has produced economies sufficient to offset its cost, the clothing manufacturer has more profits than before. (We shall assume that he merely sells his coats for the same price as his competitors, and makes no effort to undersell them.) At this point, it may seem, labor has suffered a net loss of employment, while it is only the manufacturer, the capitalist, who has gained. But it is precisely out of these extra profits that the subsequent social gains must come. The manufacturer must use these extra profits in at least one of three ways, and possibly he will use part of them in all three: (1) he will use the extra profits to expand his operations by buying more machines to make more coats; or (2) he will invest the extra profits in some other industry; or (3) he will spend the extra profits on increasing his own consumption. Whichever of these three courses he takes, he will increase employment. In other words, the manufacturer, as a result of his economies, has profits that he did not have before. Every dollar of the amount he has saved in direct wages to former coat makers, he now has to pay out in indirect wages to the makers of the new machine, or to the workers in another capital industry, or to the makers of a new house or motor car for himself, or of jewelry and furs for his wife. In any case (unless he is a pointless hoarder) he gives indirectly as many jobs as he ceased to give directly. But the matter does not and cannot rest at this stage. If this enterprising manufacturer effects great economies as compared with his competitors, either he will begin to expand his operations at their expense, or they will start buying the machines, too. Again more work will be given to the makers of the machines. But competition and production will then also begin to force down the price of overcoats. There will no longer be as great profits for those who adopt the new machines. The rate of profit of the manufacturers using the new machine will begin to drop, while the manufacturers who have still not adopted the machine may now make no profit at all. The savings, in other words, will begin to be passed along to the buyers of overcoats—to the consumers. But as overcoats are now cheaper, more people will buy them. This means that, though it takes fewer people to make the same number of overcoats as before, more overcoats are now being made than before. If the demand for overcoats is what economists call “elastic”—that is, if a fall in the price of overcoats causes a larger total amount of money to be spent on overcoats than previously—then more people may be employed even in making overcoats than before the new labor-saving machine was introduced. We have already seen how this actually happened historically with stockings and other textiles. But the new employment does not depend on the elasticity of demand for the particular product involved. Suppose that, though the price of overcoats was almost cut in half—from a former price, say, of $75 to a new price of $50—not a single additional coat was sold. The result would be that while consumers were as well provided with new overcoats as before, each buyer would now have $25 left over that he would not have had left over before. He will therefore spend this $25 for something else, and so provide increased employment in other lines. In brief, on net balance, machines, technological improvements, automation, economies, and efficiency do not throw men out of work. From the book, Economics in One Lesson, by Henry Hazlitt. This article was originally published on FEE.org. Copyright 1946 by Harper & Brothers. Reprinted by permission of Harper & Row, Publishers. Henry Hazlitt (1894-1993) was the great economic journalist of the 20th century. He is the author of Economics in One Lesson among 20 other books. See his complete bibliography. He was chief editorial writer for the New York Times, and wrote weekly for Newsweek. He served in an editorial capacity at The Freeman and was a board member of the Foundation for Economic Education.

Now it is important to bear in mind that insofar as the rioters were thinking of their own mediate or even longer futures their opposition to the machine was rational. For William Felkin, in his History of the Machine-Wrought Hosiery Manufactures (1867), tells us (though the statement seems implausible) that the larger part of the 50,000 English stocking knitters and their families did not fully emerge from the hunger and misery entailed by the introduction of the machine for the next forty years. But insofar as the rioters believed, as most of them undoubtedly did, that the machine was permanently displacing men, they were mistaken, for before the end of the nineteenth century the stocking industry was employing at least a hundred men for every man it employed at the beginning of the century.

In the depression of 1932, the game of blaming unemployment on the machines started all over again. Within a few months the doctrines of a group calling themselves the Technocrats had spread through the country like a forest fire. I shall not weary the reader with a recital of the fantastic figures put forward by this group or with corrections to show what the real facts were. It is enough to say that the Technocrats returned to the error in all its native purity that machines permanently displace men—except that, in their ignorance, they presented this error as a new and revolutionary discovery of their own. It was simply one more illustration of Santayana’s aphorism that those who cannot remember the past are condemned to repeat it.

Theories as false as this are never held with logical consistency, but they do great harm because they are held at all. Let us, therefore, try to see exactly what happens when technical improvements and labor-saving machinery are introduced. The details will vary in each instance, depending upon the particular conditions that prevail in a given industry or period. But we shall assume an example that involves the main possibilities.

So Countdown , McDonalds and New World to name a few have started rolling out automatic kiosks replacing 8 operators with 1 or 2 people who are there to ‘manually’ help the process for age checking and machine ‘malfunctions’. My guess is those 6 or 7 people are no longer required elsewhere in the operation. Magnify this across every town and city in Australia and NZ and you will see that employment options are certainly reducing due to the introduction of automation.