Published on the 26/08/2014 | Written by Abel Software

AT A GLANCE

INDUSTRY

- Automotive

BUSINESS OBJECTIVE

- Cut costs and get tighter control over all production sources

- Manage production, importing and re-exporting globally

SOLUTION

- Automating all financial, ordering, manufacturing and customer management processes using Abel ERP

THE BENEFITS

- Time spent on ordering, production control and CRM has been cut from days to hours

- Automated inventory control has cut manhours by more than half with improved accuracy

- Full visibility of key business operations at any time, all in one place

- A new e-commerce website will enable direct sales globally

FOR MORE INFORMATION

ABEL SOFTWARE

W: www.abelsoftware.com

Australia

E: davidm@abelsoftware.com

T: +61 2 9888 3355

New Zealand

E: davidm@abelsoftware.com

T: +64 9 442 4603

In a cut throat auto industry, Disc Brakes Australia relied on the agility of Abel’s ERP system, to not only survive, but thrive…

Few sectors change as relentlessly as the auto industry.

Peter O’Connor, the General Manager of Disc Brakes Australia, recalls how 15 years ago the majority of cars in his home market were locally made.

Today that balance between local and imported models has reversed with more than 60 brands in the Australian market. It’s not only the car makers who have felt the change, with the emergence of China as the world’s factory, component suppliers have either gone under or have had to find new ways to keep up.

It’s a measure of Disc Brakes Australia’s resilience that it is Australia’s only remaining dedicated disc brake rotor manufacturer. But rather than just survive it has thrived. Smart thinking has created worldwide success for this niche innovator.

Founded 40 years ago, the company has grown strongly in recent years, with continued growth in the last 12 months against the trend. Already strong in Australia and New Zealand, it is now selling more rotors globally, focusing on high performance and military vehicle applications that need something extra to stop fast.

From their Silverwater office near Sydney’s Olympic Park, Peter lists a simple formula for success: quality, availability, breadth and depth of inventory and pricing. But like any good recipe the trick is in mixing the ingredients. Four years ago they sat down and decided two changes were vital: reduce costs, and tighten control over ordering and production.

Committed to quality, they decided to become a sought-after niche player. With continued growth in volume Disc Brakes Australia is no small player. But with Chinese giants producing discs by the tens of millions a year they were never going to compete on scale. They also had to target several niches at once.

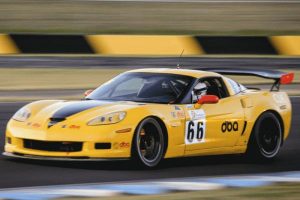

Many customers just want better value, others want performance. Disc Brakes Australia provides performance disc rotors to companies involved in all sorts of different activities including businesses that helped Top Gear drive to the North Pole, various formula type cars, “Radical” race cars, Dakar entries, rally drivers and Bathurst V8s (a video on their website shows Disc Brakes Australia’s discs running white hot around Mt Panorama). By conducting their own in-house track testing Disc Brakes Australia understands the demands their customers place on the products and they collect a whole host of data to keep the innovation alive.

With the large number of brands in the market locally and the need to be well placed to service the global performance market, the variation in parts has mushroomed, from managing 400 components, Disc Brakes Australia now manages over 7,500. It makes discs in Sydney and runs a production line in China. “As the business has evolved,” Peter says, “so the level of complexity has grown.”

In managing all this complexity he adds: “I hate to think where we might have been today without Abel.”

Before they shifted to Abel three years ago, compiling a large replenishment order for their warehouses was a three-day nightmare. Spreadsheets had to be individually compiled and compared against orders and inventory. There was a risk of doubling-up or running out. Because they were such a chore, purchase orders were done only once a month.

“Abel encompasses our business. Once you configure Abel to suit your business processes, it just delivers.”

Peter O’Connor, general manager – Disc Brakes Australia

With Abel, compiling, reviewing and finalizing a purchase order only takes an hour instead of three days using their old process. Abel automatically identifies parts that need to be ordered. “We are now placing purchase orders once a week. Abel never misses a trick, we no longer have to build a mountain of inventory, wait for it to run down and then build it again. Now we just build a small hill and keep populating it.”

Managing manufacturing was just as laborious, as supplier components had to be individually checked and ordered. Customer management relied on emails – lose one and you also might lose all previous transactions.

At a single click, they see the history of every customer transaction. Constantly tracking demands, Abel conducts its own “micromanagement” and updates the system as it goes. It runs all their finances, automatically converting between multiple currencies.

Disc Brakes Australia needed a business management system that was as fine-tuned and fast as the performance components they make. Peter says Abel has delivered beyond expectations. It has allowed Disk Brakes Australia to cut costs and waste, and reduce staff hours spent on inventory management by more than half.

“Abel encompasses our business. Once you configure Abel to suit your business processes, it just delivers. You get a system that can handle a very high level of complexity which would cost a lot more if you went anywhere else.”

And Disc Brakes Australia can do more with Abel. They recently started using Abel’s attachment architecture to store background images and technical drawings against every part number for easy checking.

Now they are planning another big step – Disc Brakes Australia will shortly launch an e-commerce website. Driven by Abel, this will connect them directly to customers all over the world, automating every step from customer selection to dispatch and delivery. It’s an exciting development, but also one where they remain well positioned to manage the demands and succeed.

Source: This article was originally sourced from Abel Software

FURTHER READING

About This Vendor

More Case Studies

Keeping customers atop the food chain

Bonson NZ packages up ERP success with Abel…

A honey of a solution for Taupo exporter

Cosana is enjoying sweet success with Abel ERP’s traceability, flexibility and ease of use…

Raising the bar for craft beer

Crafting efficiency, traceability and flexibility…

Rising to the top with real-time data

When divestment prompted leading NZ dairy solutions provider DTS to transform their systems, they turned to Abel ERP…

Automation boosts margins and efficiency

The first step for this leading provider of high-tech equipment, GTech Bellmor was to focus on driving efficiency in their front-end processes…